Sembilan Kaitan Berbahaya di Pabrik Pembuatan Baja dan Tindakan Pencegahannya

Bagian 5: peleburan tungku listrik

Sistem air pendingin tungku listrik bocor ke dalam tungku.

kali novel baru

kali novel baru

kali novel baru

kali novel baru

(2) Jangan mengganti stasiun pompa air pendingin selama bekerja.

(3) Amati dengan cermat balok berpendingin air selama peleburan dan setelah penyadapan. Jika ditemukan kebocoran air, segera hentikan peleburan, tekan untuk berhenti, dan jangan goyangkan tungku.

kali novel baru

kali novel baru

kali novel baru

kali novel baru

kali novel baru

(1) Sebelum melakukan peleburan, pastikan tidak ada air di tanah di area tersebut.(2) Periksa secara teratur ketebalan dinding lapisan tungku, kondisi bahan tahan api di kedua sisi tombak oksigen dan pintu tungku.(3) Perbaiki tungku tepat waktu sesuai dengan rencana perbaikan tungku.kali novel baru

Bagian 6: pengukuran suhu dan pengambilan sampel

kali novel baru

Pengukuran suhu manual dan pengambilan sampel di depan tungku, kecepatan putaran tungku terlalu cepat, operasi putaran tungku di luar kendali, dan baja dituangkan keluar.

kali novel baru

Ledakan lainnya, menghanguskan.

kali novel baru

kali novel baru

(2) Pengukuran suhu manual dan pengambilan sampel dilakukan di sisi pintu kebakaran, dan kenakan pakaian pelindung.

(3) Periksa sebelum peleburan apakah tidak ada air di tanah di area tersebut.

kali novel baru

Faktor risiko yang lebih besar

Kapal tanker baja cair tidak menuangkan baja pada posisi yang benar, dan ada air di tanah.

Jenis kecelakaan yang rawan terjadi

Ledakan lainnya.

kali novel baru

kali novel baru

(2) Goyangkan tungku secara perlahan.

kali novel baru

Bagian 8: peleburan konverter

kali novel baru

kali novel baru

kali novel baru

kali novel baru

Tindakan pencegahan utama

(1) Periksa apakah kapal tanker terak bergerak ke posisi pembuangan terak konverter, dan penyelarasannya akurat.

(2) Periksa bahwa tidak ada air dan limbah bebas uap air di dalam tangki terak.

kali novel baru

kali novel baru

kali novel baru

kali novel baru

kali novel baru

kali novel baru

kali novel baru

Tindakan pencegahan utama

(1) Periksa posisi katup dan sambungan sistem nitrogen apakah ada kebocoran.

kali novel baru

kali novel baru

kali novel baru

kali novel baru

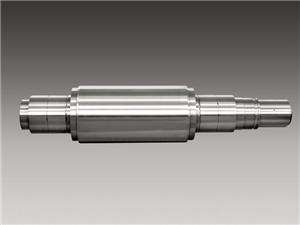

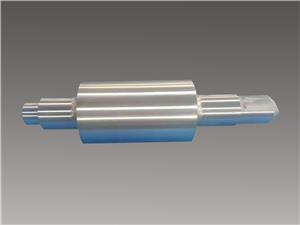

Kami membuat gulungan yang berbeda untuk baja strip panas, baja strip dingin, bagian, kawat dan tulangan juga gulungan untuk pipa tanpa sambungan. Jika ada kebutuhan, itu akan sangat dihargai!

(1) Before smelting, check that there is no water on the ground in the area.

(2) Regularly check the wall thickness of the furnace lining, the condition of the refractory materials on both sides of the oxygen lance and the furnace door.

(3) Repair the furnace in time according to the furnace repair plan.

Part 6: temperature measurement and sampling

Greater risk factors

Manual temperature measurement and sampling in front of the furnace, the furnace turning speed is too fast, the furnace turning operation is out of control, and the steel is poured out.

Types of accidents prone to occur

Other explosions, scorching.

Main preventive measures

(1) Manual temperature measurement and sampling to observe the pressure in the furnace to slowly pour the furnace.

(2) Manual temperature measurement and sampling stand on the side of the fire door, and wear protective clothing.

(3) Check before smelting that there is no water on the ground in the area.

Part 7: tapping

Greater risk factors

The molten steel tanker does not pour steel in the correct position, and there is water on the ground.

Types of accidents prone to occur

Other explosions.

Main preventive measures

(1) Check and confirm the tapping point of the molten steel tanker.

(2) Slowly shake the furnace.

Part 8:converter smelting

Greater risk factors

The slag tank is not in place, there is water or damp waste in the spilled slag tank.

Types of accidents prone to occur

Other explosions.

Main preventive measures

(1) Check that the slag tanker moves to the slag discharge position of the converter, and the alignment is accurate.

(2) Check that there is no water and moisture-free waste in the slag tank.

(3) Check and confirm that there is no water and moisture in the slag channel.

Part 9: slag splashing to protect the furnace

Greater risk factors

Nitrogen leaks.

Types of accidents prone to occur

Poisoning and suffocation.

Main preventive measures

(1) Check the valve position and joints of the nitrogen system for no leakage.

(2) Check that there are ventilation facilities in the nitrogen valve room and there is no leakage.

(3) Before entering the nitrogen and argon valve chambers for inspection, ventilate and check with an oxygen detector before entering.

It is necessary for take care of each details in steel making company.And wish every steel company with safety production!

We make different rolls for hot strip steel,cold strip steel,sections,wire and rebar also rolls for seamless pipe.If any need,it will be highly appreciated!